ATEX and IECEx: The certifications for explosion protection explained in a way that is easy to understand

Ensuring explosion protection is one of the most important tasks of manufacturing companies and manufacturers of Ex products. After all, human lives depend on the corresponding hazards being ruled out as far as possible. There are usually two certification systems for this to indicate that devices are protected against explosions: ATEX and IECEx. The former is based on legal regulations that were issued according to directives of the European Union. IECEx is a non-governmental scheme under the auspices of the International Electrotechnical Commission (IEC). This article explains the systems and shows what similarities and differences both variants have.

ATEX and IECEx in profile

ATEX

ATEX as a term has established itself as a synonym for the EU directives on explosion protection. The acronym itself is short for the French phrase “Atmosphères Explosibles” (“Explosive Environments/Atmospheres”). Two ATEX directives are important here: the ATEX company directive 1999/92/EG for the operator and the ATEX product directive 2014/34/EU for the manufacturer.

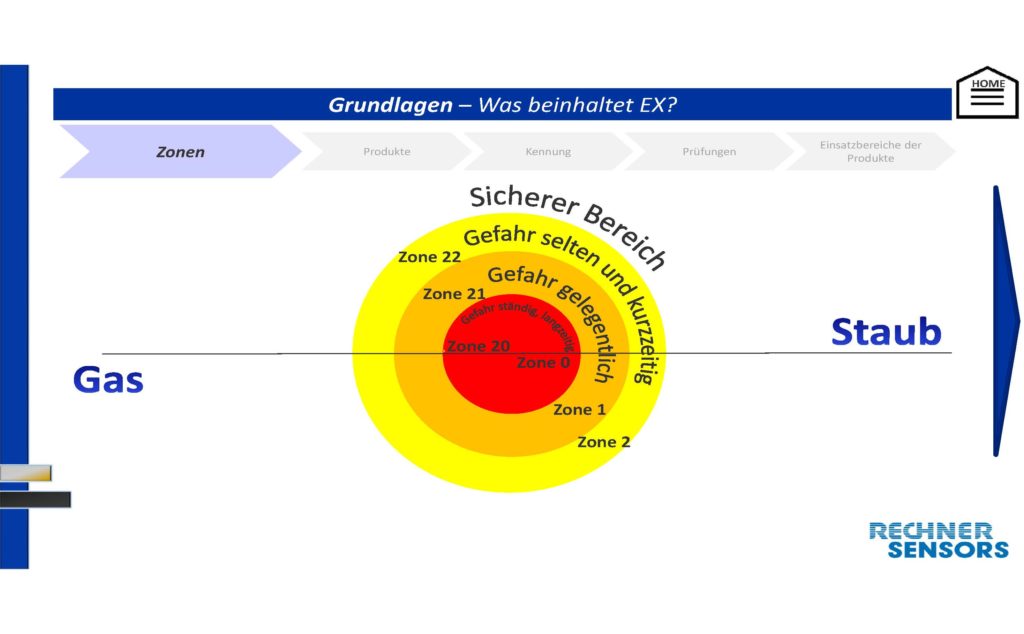

The Works Directive sets minimum requirements aimed at improving the health protection and safety of people working in potentially explosive atmospheres. Employers must create an explosion protection document in which hazards are explained transparently. In addition, potentially explosive environments must be divided into zones depending on the degree of risk frequency.

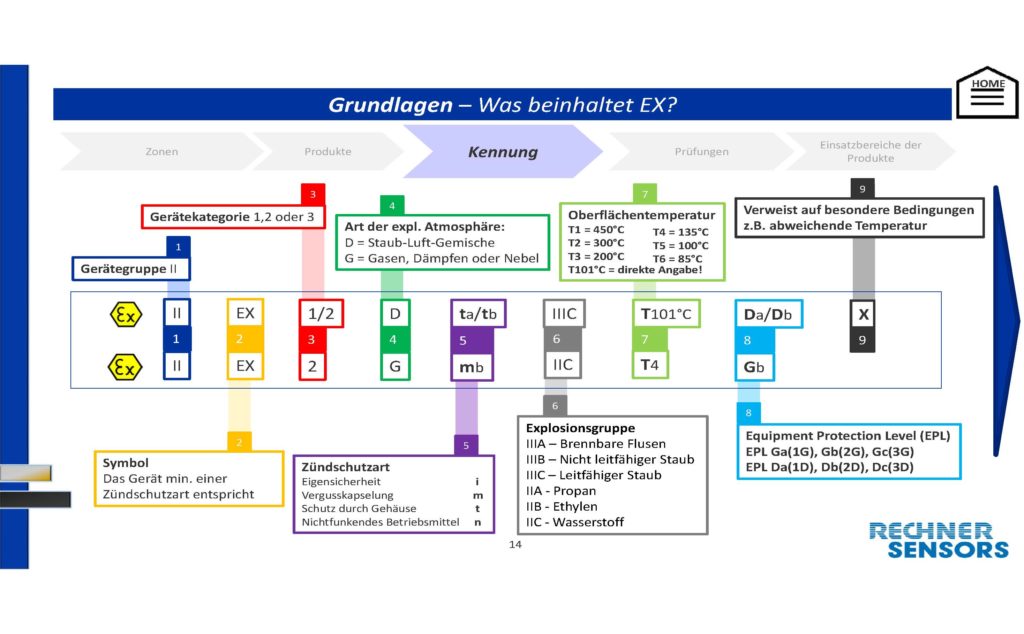

The product directive contains specifications for products that are used in potentially explosive environments. This also includes non-electrical devices. The directive divides products into two groups and then distinguishes them according to specific categories. The two groups are:

1. Equipment “I” for use in mining companies or similar operations (categories: M1 = very high security, M2 = high security)

2. Equipment “II” for use in potentially explosive dust and gas atmospheres (categories: in zones and explosion groups)

The individual categories must be described further, for example with the duration of the hazard. In addition, six temperature classes are defined that regulate the permissible surface temperatures. They are denoted by T1 to T6. T6 is the most critical because it is the lowest permissible surface temperature.

In a certification body (e.g. Dekra), the products are classified (group and category) and certified according to the guidelines prescribed in the guidelines. The logo bears the letters Ex.

IECEx

IECEx stands for “International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres” or “International Procedure for the Certification of Electrical Equipment Used in Hazardous Areas.” IECEx would like to harmonize the international regulations for explosion protection. The goal is for assessment and audit reports (ExTRs) to be mutually recognized around the world. Similar to ATEX, IECEx has regulations that categorize environments into specific hazard classes. Some of the standards issued by the IEC, such as IEC 80079-0, IEC 80079-18 and IEC 80079-31, are decisive. As with ATEX, certificates are also issued with IECEx via an external certification body. In Germany, for example, this is Dekra. The associated certificate is labeled IECEx.

ATEX and IECEx: What both systems have in common

Both systems are fundamentally similar. Explosive atmospheres with gas are divided into zones 0, 1 and 2. Zone 0 / Zone 20 is with the highest (greatest) risk of explosion. For the dust, the zone designations are 20, 21 and 22. In zone 20 there is constant danger.

Differences between ATEX and IECEx

Among other things, ATEX requires a general conformity assessment by an external body. Only equipment that is used as equipment category 1 from zone 0 or zone 20 must be assessed by an external certification body. For Zone 22 and Zone 2, estimates (personal responsibility) by the respective manufacturer are sufficient. IECEx only recommends external testing here. Provided the company has been certified by an external body for ATEX production and ISO 9001.

The main difference is due to the geographic areas (European area / international area)

More information about ATEX and IECEx. Download ATEX overview now

Inductive sensor

Find out everything about the assembly and functionality of an inductive sensor.

Capacitive filling level measurement

Find out everything about the process and functionality of capacitive filling level measurement.

Filling level sensor

Find out everything about the assembly and functionality of the filling level sensor.